Hazardous Materials News, Regulations & Blog

Why Excel and Paper Binders Are No Longer Enough to Manage Your SDS

For many companies, Safety Data Sheet (SDS) management still relies on two pillars inherited from the 90s: Excel spreadsheets and heavy yellow three-ring binders.

More details

What is WHMIS? A Complete Guide to Canada’s Workplace Hazardous Materials Information System

WHMIS stands for Workplace Hazardous Materials Information System. It is Canada’s national standard for how hazard information is classified and communicated in workplaces that use, handle, store, or dispose of hazardous products.

More details

Kalium Solutions: Celebrating 10 Years of Excellence in Chemical Compliance

On August 15, 2025, Kalium Solutions celebrates a remarkable milestone — 10 years in business of chemical compliance.

More details

New Classes on European SDS: What You Need to Know?

The landscape of chemical safety within the European Union (EU) is constantly evolving, driven by the imperative to protect both human health and the environment.

More details

How Chemical Safety and Compliance Are Improved by On-Demand SDS Programs?

Ensuring the safety of workers and maintaining compliance with safety regulations is paramount. With increased workplace hazards and environmental concerns, businesses must prioritize chemical safety.

More details

Important WHMIS Update: Upcoming Deadline for SDS and Label Compliance

Canadian businesses handling hazardous products, take note! The clock is ticking towards a crucial deadline for compliance with the WHMIS 2015 update.

More details

Proposed Modifications to Transportation of Dangerous Goods Regulations

Transport Canada has been working on a revision of Part 6 of the Transportation of Dangerous Goods Regulations (TDGR) for several years now.

More details

OSHA HCS 2024 Update: Key Changes, Deadlines, and Compliance Checklist

Introduction: What Changed on July 19, 2024

On July 19, 2024, OSHA updated the Hazard Communication Standard to improve hazard clarity for workers and align U.S. practice with the Globally Harmonized System. The rule primarily aligns with GHS Revision 7, while referencing selected elements consistent with Revision 8 where OSHA incorporated them. The update sharpens hazard classification, refines Safety Data Sheet requirements, clarifies supplier information, and adjusts labeling rules so employers can communicate risks more accurately and consistently.

More details

Persistent Chemicals and Endocrine Disruptors Regulation in Europe, PBT - PMT

The Classification, Labelling and Packaging (CLP) Regulation is the European Union regulation defining the rules that must be respected for hazardous products in Europe, whether they are industrial products or those made available to the public. This regulation uses the classification of the UN Globally Harmonized System.

More details

Child-resistant containers under the CCCR, CPSC and CLP regulations

Whether in Canada under the CCCR, in the United States under the CPSC or Europe under the CLP, child-resistant containers are an important regulatory element in the sale of hazardous consumer products.

More details

Understanding CMR Agents: What They Are and How to Manage Their Risks

Understanding carcinogenic, mutagenic and reprotoxic chemical agents (CMR): what they are and how to manage their risks in the workplace

More details

New CCCR Requirements: Integrating Chronic Hazards and GHS Alignment

Health Canada held a multilateral workshop on the CCCR on November 7, 2024. The goal is to amend the CCCR regulations to better protect consumers and workers.

More details

How to Prevent Chemical Spills and Improve Workplace Safety

Businesses and industries rely on chemicals for countless tasks. However, chemical spills pose significant safety risks to every person in the workplace. These spills can harm workers, ruin equipment, and damage the environment. Even a small accident can lead to major problems if not handled well.

More details

Benefits of WHMIS training via videoconference with our experts

It is imperative that workers understand safety procedures in today's hectic work environment. In Canada, the Workplace Hazardous Materials Information System (WHMIS) is essential to upholding safety regulations in a variety of sectors. WHMIS training has moved from traditional classroom settings to online platforms with the introduction of technology. Numerous advantages have resulted from this change, including increased accessibility, effectiveness, and efficiency of WHMIS training online. Let's explore the benefits of online WHMIS safety training and discover why so many businesses choose it.

More details

Top 5 Factors to Consider When Selecting SDS Management Software

SDSs are commonly employed to ensure occupational safety and regulatory compliance in today’s safety-conscious world. They provide essential information regarding hazardous chemicals used in the workplace, such as possible dangers, ways of handling them safely, and what to do during emergencies.

More details

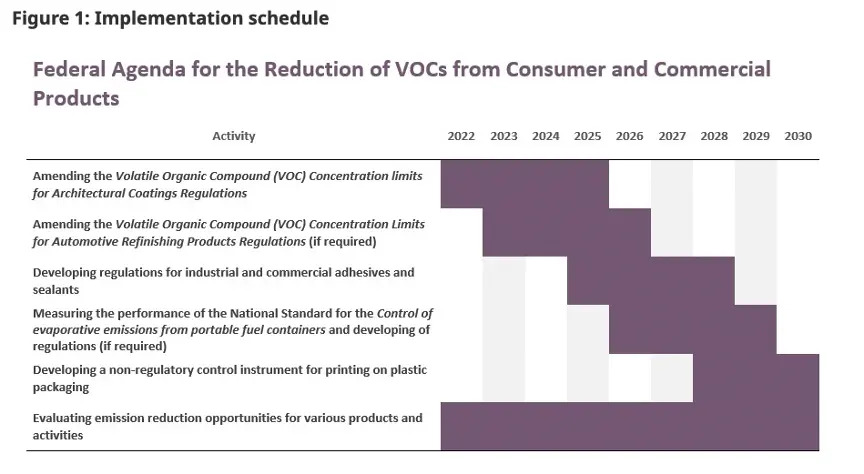

VOC regulations for Certain Products in Canada

- Here is our article 2 of 2 on volatile organic compounds and the new regulations. In this article, you will not only find the important dates to remember to comply with the new VOC regulations, but the possible alternatives. The Regulations limiting the concentration of volatile organic compounds in certain products will come into force on January 1, 2023 to provide one year for permit applications and the accumulation of compliance units before the limits applicable to the products come into force.

More details

Reducing Volatile Organic Compound (VOC) Environment Emissions

This has been expected for several years, with the effects of climate change and after the enforcement of regulations limiting the concentration of volatile organic compounds (VOCs) in architectural coatings and automotive finishing products, Environment Canada has finally filed the Regulations limiting the concentration of volatile organic compounds in certain products: SOR/2021-26. Consumer product manufacturers, watch the dates!

More details

Online application form for exemption requests under the HMIRA

What to do to maintain your business advantage if your critical ingredients are classified as hazardous to health in your safety data sheet? You have two options:

- Apply for a paid waiver under the HMIRA

- Use concentration ranges

Why choose an exemption?

More details

New Database for TDG

On June 25th, 2022, Transport Canada published in the Gazette I, its proposal to amend the TDGR, adding a new obligation. Businesses will have to register on the registration database and renew their registration annually.

More details

CANUTEC, Canada's free emergency service for dangerous goods in transport

To get rid of your residual hazardous materials, do you take a turnkey service (classification of your products, packaging, labelling, completed documentation) from a company specializing in waste management?

To understand the difference:

More details

Travelling With Electronic Devices Containing Lithium Batteries

Do you need to send electronic devices containing lithium batteries for calibration? For repairs? To a new employee? Do you bring electronics on your travels?

Read on for all the answers!

More details

How to Properly Store and Dispose of Your Lithium Batteries

Lithium batteries are a recurring problem for Sorting Centers and Ecocentres. In this article, discover the little things you can do to reduce the risk of accidents.

More details

Underestimated Hazard: Lithium Batteries!

How many lithium batteries do you have at home? At work? For the most part, you are probably unable to give an exact number. Indeed, you would be surprised at the number of devices that contain lithium batteries. Read on to fully understand the dangers of your batteries.

More details

WHMIS Classification: State Matters

When classifying a mixture, several criteria must be considered. Adding up the hazards of each ingredient is not enough. The classification of a mix is much more complex than the simple addition of its constituent parts. We need to go beyond simply enforcing regulations. We should perform physical tests to support our decisions. Ask yourself: Did my ingredients react? Has neutralization occurred? Is substance X still bioaccessible?

More details

GHS - Disputed Harmonized Classification: The Titanium Dioxide Dilemma

For decades, titanium dioxide and carbon black have not been unanimously accepted in terms of classification.

Despite the Globally Harmonized System (GHS), recently in Europe, a formal challenge in court has taken place.

Dilemma or misunderstanding? Read more

More details

Design, programming and hosting by VisionW3.com