Workplace Hazardous Materials Information System WHMIS labels implementation

Do you need help for your WHMIS implementation 2015 in your organization?

You are in the right place! At Kalium Solutions, you will find all the resources you need to ensure a complete and successful WHMIS implementation. Our goal is to help you meet regulatory requirements and protect your workers. We will provide you with a clear action plan and tools to manage WHMIS in your organization and to keep it up to date.

Our team of expert chemists are here to help you implement best practices and ensure compliance with health and safety rules and regulations. We offer you tailor-made services so that you can benefit from a complete and fast solution to meet your WHMIS needs, including WHMIS workplace labels and WHMIS 2015 labels.

We understand the importance of health and safety in the workplace and are committed to providing you with top quality services and solutions. We also offer follow-up and assistance services to help you implement WHMIS but also to ensure its sustainability.

Implementing WHMIS with Kalium solutions means investing in health and safety while having a substantial return on investment.

Here is a detailed list:

|

|

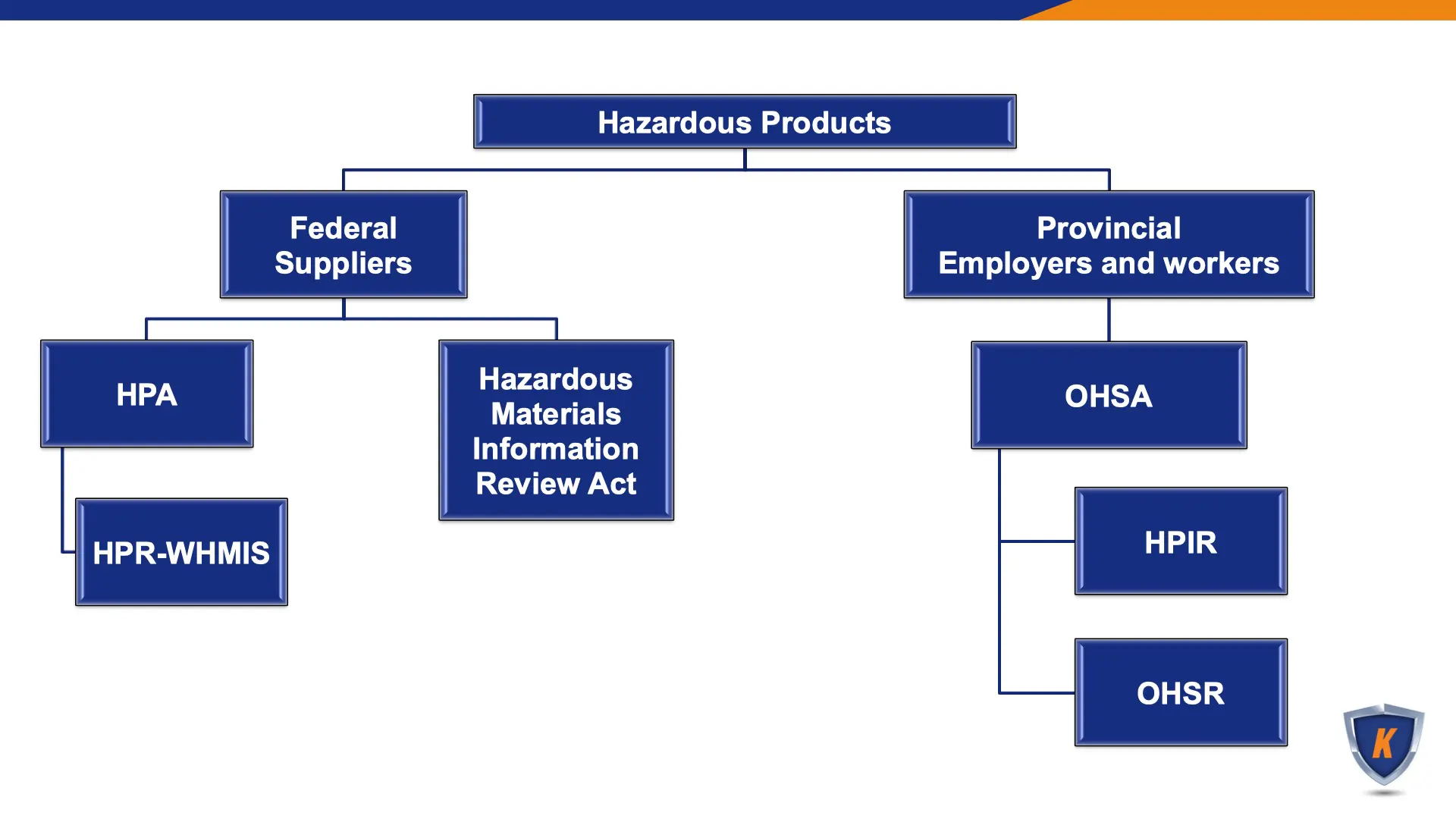

Hazardous Products |

|||

|

Federal |

Provincial |

||

|

HPA |

Hazardous Materials Information |

OHSA |

|

|

HPR-WHMIS |

HPIR OHSR |

||

Our approach is fully compliant with the Health and Safety Act and its OHSR regulations and also with the Hazardous Products Information Regulations (HPIR). This regulation manages information, the information and training program for workers, labeling and the storage of dangerous products in the workplace. The amended HPIR has been in effect since June 1, 2015.

- Labeling of hazardous products such as workplace labels

- Rules relating to certain containers

- SDS such obligation to produce, keep, replace and update

- Display of safety data

- Training and information program which must contain the following elements in particular:

- Information on the nature and meaning of the information contained on a label, a poster and in a safety data sheet;

- Training on hazard information, including hazard statements and precautionary statements, for each of the hazardous products present in the workplace;

- Training on applicable directives so that the use, handling, storage, warehousing and disposal of hazardous products, including those contained in a pipe, tank car, tank etc;

- Training on the precautions to be taken with regard to fugitive emissions, intermediate products as well as hazardous residues, present in the workplace, if applicable;

- Training on the procedure to follow in the event of an emergency;

- Training on where the safety data sheets are kept, how to access them, the technology relating to the medium on which they are kept and how to transfer them to a paper medium.

Whether you are a small, medium or large business, manufacturer, distributor or simply a user of hazardous materials, we have the tools, software and the right solution for you!

Frequently asked questions

Why Are WHMIS Labels Important?

WHMIS labels are the first line of protection of a worker using, handling or storing a hazardous product. They give the workers a lot of necessary information for their safety, such as the hazards associated with the product and the precautionary statements for prevention, response, storage and disposal.

What are the main differences between WHMIS 1988 and WHMIS 2015?

There are many differences between WHMIS 1988 and WHMIS 2015. WHMIS 1988 included 6 hazard classes, from A to F; WHMIS 2015 includes 32 hazard classes, and is largely based on the General Harmonized System (GHS). WHMIS 2015 uses the GHS pictograms, which easily recognizable by their red bordered diamond shape.

Here are a few advantages of WHMIS 2015:

- More comprehensive hazard classification criteria that allow for a more accurate definition of the severity of hazards

- New hazard classes have been added. This provides a better management of chronic health hazards.

For instance, under WHMIS 1988, hazard class D2 – Materials Causing Other Toxic Effects has been replaced by the following classes:Amongst the new hazard classes are some that did not have an equivalent under WHMIS 1988:

- Respiratory Sensitization

- Skin Sensitization

- Carcinogenicity

- Germ Cell Mutagenicity

- Reproductive Toxicity

- Specific Target Organ Toxicity – Repeated Exposure

- Skin Irritation

- Eye Irritation

- Aspiration Hazard

- Specific Target Organ Toxicity – Single Exposure

- Poussières combustibles

- Simple Asphyxiants

- The criteria for physical hazards are compliant with the Transportation of Dangerous Goods Regulations (TDG)

- The language used is standardized (precautionary and hazard statements)

- The format of Safety Data Sheets (SDS) is standardized and more comprehensive requirements are provided

All these benefits from using GHS as the reference for WHMIS 2015 make for a more consistent across countries, which facilitates international trade.

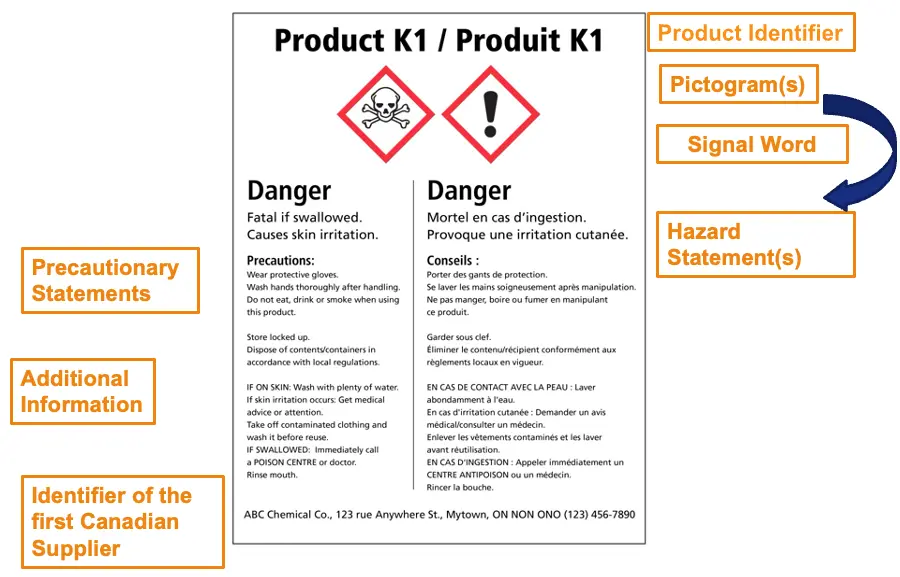

What are the new labeling requirements for WHMIS 2015?

Besides being based on the classification of WHMIS 2015, labels require 7 essential information (HPR, art. 3(1)):

- Product Identifier

- Supplier Identifier (address and phone number in Canada)

- Pictograms

- Signal Word

- Hazard Statements

- Precautionary Statements

- Additional Information (If Applicable)

Additionally, Pictograms, Signal Word and Hazard Statements must be grouped on the label, and the information must be presented in the two official languages, French and English. Here is an example of a compliant label:

Who is responsible for implementing WHMIS?

In Quebec, the Loi sur la santé et la sécurité au travail states the employer is the one who must implement a training and information program on hazardous products (LSST, art. 62.5). Other Canadian provinces have their equivalent acts, and for all of them the responsibility of implementing WHMIS also belongs to the employer. However, this does not mean the employer is the sole responsible for insuring occupational health and safety. The following table shows the different responsibilities of suppliers, employers and employees:

| Suppliers | Employers | Employees |

|---|---|---|

|

Classify hazardous products |

Provide the education and training program on workplace hazards for employees |

Participate in the education and training program |

|

Label the products |

Make sure to obtain SDS’s and labels from suppliers of hazardous products or prepare them yourself if missing |

Understand labels and Safety Data Sheets |

|

Supply SDS’s and adequately labelled products to the buyer |

Make sure SDS’s are accessible to workers (consistent with labels) |

Work with the Health and Safety Committee and use the acquired knowledge |

|

Ensure that SDS information is up to date |

Provide information resources to promote understanding of the knowledge acquired. |

Participate in the identification and control of the hazards and wear PPE |

What are the first steps to implementing WHMIS in my workplace?

It is essential to assess potentially hazardous products in the workplace. Here are the six steps to follow. You will need to:

- Conduct a complete inventory. During this step, make sure you have a SDS for each product, as well as a compliant label.

- Classify your products and determine the incompatibilities of each one.

- Arrange the premises to prevent incompatibilities (safe storage).

- Develop a WHMIS training program.

- Establish internal procedures for handling, storage, and disposal.

- Make SDSs accessible to all workers.

When it comes to making SDSs accessible, a paper binder is often the first solution that comes to mind. However, this option may not be optimal for your business since it requires maintenance and periodic checks to ensure that no SDSs are missing in the event of an incident. An electronic binder is another, slightly more efficient option. However, you must ensure that the SDSs are easily accessible and labelled so that they can be quickly found in the event of an incident. The most suitable and effective solution for a workplace is an SDS management software, which will allow you to quickly find the SDS for the desired product, in addition to printing WHMIS and workplace labels as needed. The choice of solution will be greatly influenced by the number of products present on site. If you have more than fifty different products, the software solution is by far the best option and will simplify access to SDSs thanks to the search capability. Even though the number of products is smaller, the benefits of software are numerous.

At Kalium Solutions, when we receive implementation requests, we start with a comprehensive audit. This allows us to better assess your situation and offer you a solution tailored to your business.

How do I conduct a hazardous products inventory?

Creating an inventory of hazardous products is an essential step in complying with WHMIS and protecting employee health. To do so, follow this simple, structured method:

- Identify all chemicals.

- Collect Material Safety Data Sheets (MSDS) for all identified products.

- Ensure that all labels are compliant and replace any that are missing, damaged, or illegible.

- Create an inventory register with the associated risks for each product.

- Schedule a periodic review.

Once the inventory is complete, it will be important to classify the products properly and organize the space to ensure safe storage. Our Chemicals storage software can help you place your products and identify incompatible products.

What are the requirements for workplace labels and how do I create them?

According to the Hazardous Products Information Regulations (HPIR) and WHMIS 2015 guidelines, a workplace label must contain three essential elements:

- Product name: identical to that indicated in section 1 of the SDS

- Precautionary statements

- Reference to the SDS

These are the three mandatory elements. However, it is possible to add additional information, such as personal protective equipment (PPE) and/or WHMIS pictograms.

How do I ensure our Safety Data Sheets (SDSs) are compliant and accessible to all employees?

SDSs must comply with the requirements of WHMIS 2015, 2022 revision. Here are the main differences between WHMIS 2015 and WHMIS 2022:

- New physical hazard classes and categories have been added, including for "chemicals under pressure" and subcategories for "flammable gases." There are also new categories for non-flammable aerosols. Some classification criteria for existing hazard classes have been updated to aid understanding.

- Safety Data Sheets (SDSs) also have new requirements: the 2022 revision made several information fields mandatory in Section 9 of the SDS, namely physical and chemical properties. For example, appearance, physical state, color, flammability, and viscosity have been modified or added. Field Removal: Certain fields, such as odor threshold and evaporation rate, have been removed from the requirements of Section 9.

- Here are the other key points to validate:

- 16 mandatory sections, in the prescribed order (identification, hazards, composition, first aid, etc.)

- Up-to-date information, including: hazard classification, pictograms, hazard statements, protective and emergency measures

- Language: SDSs in Canada must be available in French and English.

To make SDSs accessible to all employees, you will need to create a digital or paper registry. Among the digital options, Kalium SDS management software is our solution of choice.

You will also need to write an SDS for all products manufactured on site, whether they are finished products, intermediates, or in-house analytical solutions. Our SDS authoring software will make this task much easier for you. We can also write them for you with our turnkey service.

What should be included in a workplace-specific WHMIS training program?

In the Hazardous Products Information Regulation (HPIR):

«A training and information program must include

(1) information on the nature and meaning of the information on labels, signs and safety data sheets;

(2) training regarding information on hazards, including hazard statements and precautionary statements, for each hazardous product present in the workplace;

(3) training regarding the directives applicable to ensure that hazardous products, including any contained in a pipe, system of pipes with valves, process vessel, reaction vessel, tank car, tank truck, ore car, conveyor belt or any similar equipment, are used, handled, stored and disposed of safely;

(4) training regarding the precautions to take with respect to any fugitive emissions, intermediary products undergoing reactions in a reaction vessel or process vessel, and any hazardous waste if any of them are present in the workplace;

(5) training regarding the procedure to be followed in an emergency; and

(6) training regarding the place where safety data sheets are kept, how to access them, the technology relating to the medium on which they are kept, and how to transfer them to hard copy.» (HPIR sect. 30)

How do I assess the effectiveness of our WHMIS implementation and training?

Exercises are the best way for an employer to assess their employees' understanding. Employers must repeat exercises annually to ensure that the information received is retained.

Our WHMIS training includes practical exercises for each of the modules covered to ensure that the learning is fully integrated. The training also ends with a written knowledge assessment.

How do I manage WHMIS for products that are decanted or transferred from their original containers?

When decanting or transferring a product, it is important to choose a container that is suitable and compatible with the product. You must ensure that the container chosen is new or has been officially washed and purged.

A compliant WHMIS or workplace label must also be affixed. The only products that do not require a label are those that are used immediately by the same worker without leaving their workstation.

What are the procedures for reviewing and updating our WHMIS program?

It is necessary to establish an annual or semi-annual schedule for reviewing the program, using a comprehensive checklist, updating MSDSs and labels, reassessing training needs, ensuring compliance with internal procedures, documenting changes, and monitoring regulatory changes.

In HPIR : «The training and information program must be updated annually or as soon as the situation requires it, including

(1) if a new hazardous product for which the workers have not received training or information is present in the workplace; and

(2) if a change occurs in the workplace that has an impact on work methods, on the risks of exposure to a hazardous product or on the procedure to be followed in an emergency.» (HPIR sect. 31)

How can I get expert help to ensure my WHMIS implementation is fully compliant with regulations?

We will be happy to support you in all stages of implementing WHMIS in your workplace. You can contact us through our website, or by calling 450 906-6999

Design, programming and hosting by VisionW3.com