Chemicals Safe Storage and training

Safe Storage Management

Do you know how to store your hazardous materials?

Are you able to recognize incompatibility? Do you know how to separate your chemicals? We have safe storage training that will help you have a safe warehouse that complies with the Building Safety Code and the National Fire Code of Canada (NFCC).

To have safe storage, it must also comply with the provisions of the Health and Safety Act (OHSA) of its province and its regulations, such as the ROHS (particularly section X) in Quebec.

Depending on the situation, the Building chapter of the Safety Code, the National Fire Code of Canada (NFCC) and the NFPA may also apply.

From the law on occupational health and safety also comes the Regulation on information concerning hazardous products (RIPD), it stipulates that your employees must be trained in the storage of hazardous materials.

According to article 72 of the Quebec ROHS, the storage and handling of hazardous materials must be carried out in such a way as to prevent their spillage or accidental ignition.

To this end, it is necessary to separate or isolate hazardous materials which, by mixing with other materials, are likely to cause a fire or an explosion, or to release flammable or toxic gases.

To properly separate your products, it is imperative first, to have a list of all your well-classified products. Once the classification is done, all the products must be correctly segregated according to the standards and regulations in force.

In summary, these are the 5 steps required to achieve safe storage:

- The inventory

- The classification

- Identification (labelling)

- Validation of incompatibilities

- The layout of your workplace

Need help? Our software can provide you with a complete assessment of your situation and suggests a totally safe layout from a chemical point of view.

Looking for a training in chemical storage?

Register now to ensure your organization's security and compliance.

1 - Summary and objectives of the training

Chemical storage, a must for the health and safety of Workers

The safe storage of hazardous materials is part of a comprehensive risk management approach. Ignorance of storage rules can lead to serious consequences, such as:

- Violent reactions that can cause serious injury (explosion or splashes on the skin or in the eyes, falls from the same level, etc.)

- Emission of toxic or flammable gases

- Fires

- Explosions

- Spill that may impact the environment

Why is the regulation of chemical storage complex?

Several ambiguities, even contradictions, are present through the regulations in force in North America and elsewhere. There are several chemical incompatibility charts that are part of the transport’s regulation: in the IMDG (Table 7.2.4 of the IMDG Code), in the CFR 49 (US transport of dangerous goods) and even in WHMIS. The ROHS also contains several articles of legislation specifically for this purpose (Division X sections 70 to 100).

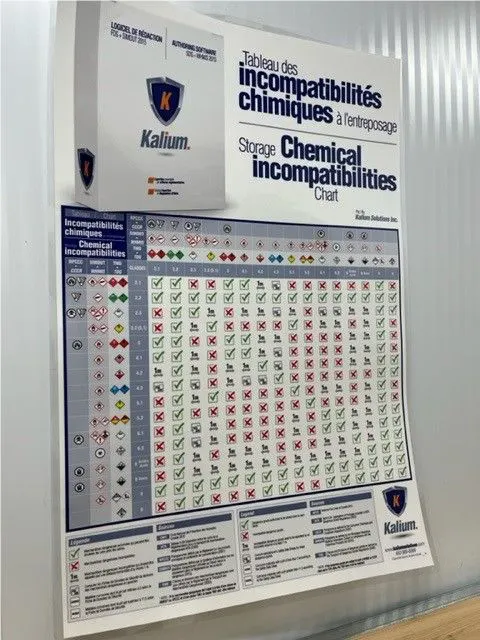

To address this issue, experts have tried to develop some tools. We have developed a table of incompatibility that includes both TDG, 49 CFR, CCCR, WHMIS and IMDG in the most comprehensive form possible. However, the various tools developed to overcome regulatory ambiguities do not allow for the inclusion of all exceptions. An update through continuous training therefore becomes a must to keep workplaces safe.

Develop Professional Judgment to Ensure the Safety

The regulation of hazardous materials was developed from the chemical classes of the compounds of a product. Therefore, safe storage of chemicals requires minimal knowledge of the different classes of chemicals. With the increasing complexity of products available on the market, it is increasingly difficult to correctly identify the chemical classes of a product. An error at this level leads to poor risk assessment and storage of potentially incompatible compounds, which represents a risk to the health and safety of environmental workers. Therefore, keeping one’s skills up to date is a way to preserve one’s ability to assess/judge chemical hazards. The approach provided by this training is purely practical and, inevitably, is intended to compensate for regulatory deficiencies using professional judgment.

Who is this training for?

The complexity of storage regulations and lack of knowledge can put some workplaces at risk of accidents. This training is intended for professionals who are involved/supervise the management and storage of chemicals or who wish to update their knowledge of chemical product classification in a storage context. The aim is to better assess chemical incompatibilities and better judge accident risks. With the growth and complexity of chemicals on the market, this training finds its place in a multitude of environments, such as laboratory workers, manufacturing workers, food products, pharmaceuticals, OHS managers, or any other worker who wants to make workplaces more efficient and safer.

Let’s not forget that hazard assessment starts with knowing the risks associated with a hazardous product.

- What do I do with corrosive and flammable products in storage?

- Can glacial acetic acid be stored with nitric acid?

- Is it safe to store 64% nitric acid (non-oxidizing according to WHMIS and TDGR) with glacial acetic acid, ascorbic acid and hydrochloric acid?

Overall Training Objectives

This training allows you to review the various regulations applicable to storage. Its main purpose is to develop professional judgment related to the storage of chemicals. Chemists and biochemists act as experts in the workplace, and they are the first line of safety intervention. They have an ethical and deontological obligation to ensure the safety of workplaces regarding chemical risks. The general objectives of the training are to update the professional’s knowledge for safe storage of products in the workplace and develop the professional judgment of the chemist or biochemist to overcome current regulatory gaps.

To achieve these overall objectives, these elements will be addressed:

- Know the classification of chemicals in a storage context

- Recognizing chemical incompatibilities through different labelling systems

- Be able to assess the risks according to the chemical class of the product, Know the risk management principles related to the storage of chemicals, and be familiar with the main storage rules

- Know information resources for chemical storage

2 - Training outline

Module 1: Introduction (WHMIS Brief, Risk Management Principle)

Module objectives:

Be able to:

- Analyze the potential of H and P phrases and WHMIS pictograms in storage

- Assess the limitations of the current labelling system

- Distinguish the risks in storage not covered by WHMIS

- Understand the different labelling systems in Canada, WHMIS, TDG, CCPR, PMRA etc.

- Align TDGR pictograms to address WHMIS gaps

- Understand the need for comprehensive classification.

Sub-objectives

1.1 Risk management principle and primary objective of training

1.2 WHMIS and HPR labelling recall

1.2.1 H and P phrases

1.2.2 Incompatibilities under the same WHMIS pictogram

1.2.3 Example of missing information

Module 2: Storage of flammables, oxidizers, aerosols and gases

Module objectives:

Be able to:

- Judge the applicability of the WHMIS segregation table

- Align TDGR pictograms to fill WHMIS gaps

- Analyze situations where flammable storage may be problematic

Sub-objectives

2.1 Physical hazards under the flammable pictogram

2.2 Imminent risks of incompatible storage under WHMIS

2.3 Using TDGR to address WHMIS gaps

2.4 Ignition Source Management

2.5 Oxidant Management

Module 3: Storage of Corrosive and Toxic

Module objectives:

Be able to:

- Judge the real incompatibilities of corrosives and flammables

- Judge the level of incompatibility between acids and bases

- Distinguish acids and bases with uncommon names

Sub-objectives

3.1 Difference Between Acid and Base Burn

3.2 Obligations to have eyewash stations and body washers

3.3 Acid-base distinction

3.4 Toxics and other health hazards

Module 4: General rule of storage

Module objectives:

Be able to:

- Know the principles of incompatibilities

- Know how to recognize certain regulatory incongruences

- Familiarize yourself with certain storage rules

Sub-objectives

4.1 Principle with 4 variables of incompatibilities

4.2 Storage example

4.3 Actual vs. WHMIS incompatibility (regulatory inconsistency)

4.4 Broadening the definitions of oxidant, acid, base and flammable

4.5 Special rule: acidic water reagent, basic.

4.6 Storage of products with specific incompatibility (cyanide, azide, sulphides)

Module 5: Handling and Storage of Hydrofluoric Acid (HF)

Module objectives:

Be able to:

- Preventing serious incidents involving HF

Sub-objectives

5.1 Properties of hydrofluoric acid

5.2 Exposure procedures

5.3 Recommendation of pick-up procedure

Module 6: Use of External Information Resources

Module objectives:

Be able to:

- Prevent rust from forming in cabinets

- Confirm the accuracy of the information conveyed on a product

Sub-objectives

6.1 Corrosion management in cabinets

6.2 Using External Resources

Poster of chemicals incompatibilities

Size: 24" X 36"

Paper Stock: Semi-Gloss

Orientation: Vertical

Price: 100$ + tx + shipping.

To order: 450 906 6999

or

Frequently asked questions

1. What is safe storage, and why is it important for hazardous materials?

Safe storage is a set of practices that prioritize the safety of employees and the environment. It helps prevent accidents and minimizes damage in case of an emergency. It is a requirement in all workplaces that handle hazardous materials.

Properly storing hazardous materials requires a focus on preventing unintentional spills, leaks or accidental ignition.

To achieve this, you must:

- Isolate hazardous substances that, when combined with other materials, can ignite, explode, or emit flammable, corrosive, or toxic gases.

- Take care to prevent damage to containers, shelves, racks, compartments, piping, and other equipment.

- Promptly and safely address any spills of hazardous materials, using appropriate equipment, regardless of location.

- Consider incompatibilities when transferring hazardous materials between containers.

In the event of a spill, fire, or other emergency, safe storage minimizes risks and damage. It also facilitates the work of first responders, prevents incidents, and uncontrolled reactions, and can reduce insurance costs.

2. What types of hazardous materials can be stored safely?

In Canada, the storage and handling of hazardous materials in the workplace are governed by provincial occupational health and safety regulations (OHSRs). These indicate the storage rules that must be followed for:

- Compressed gases

- Aerosols

- Flammable and combustible materials

- Oxidizing materials

- Toxic materials

- Corrosive materials (acids and bases)

- Dangerously reactive materials

In the United States, the National Fire Protection Association (NFPA) develops codes, standards, and recommended practices through a consensus process approved by the American National Standards Institute (ANSI). The resulting documents cover a very wide range of hazardous materials and serve as a global reference. For instance, NFPA 30 regulates the storage and handling of flammable and combustible liquids. Meanwhile, NFPA 30B addresses the storage of aerosols. NFPA 40 establishes guidelines for storing and manipulating cellulose nitrate films. If you have liquid or solid oxidizers, NFPA 430 is a good option. For the full list of NFPA codes and standards, click here.

Kalium Solutions can help you store any type of hazardous material safely. In addition to the hazard classes mentioned above, we can also help you with the following:

- Materials that deteriorate over time

- Hazardouss waste

- Biological hazards (biohazards and toxins)

- Other regulated materials

Our solutions, training, and secure storage software take into account not only the primary risks, but also the secondary and tertiary risks of these materials.

For example, nitric acid is not only corrosive and acidic, but also an oxidizer. Nitric acid and glacial acetic acid should never be stored together, as the latter is both flammable and corrosive.

It is crucial not to overlook any hazard category, but rather to accurately categorize all potential dangers. Therefore, these two acids, despite sharing the same corrosive nature, must not be kept in the same place.

The most frequent hazardous mixtures are:

- Flammable + oxidizers

- Acids + Bases

- Water Reactive Materials + Water

3. What measures does Kalium Solutions take to guarantee secure storage?

Safe storage is not a defined regulation. It is an amalgamation of several regulations and standards. It’s crucial to note that the requirements for secure storage may differ based on the storage location.

Although the basis is the same, for example, a cargo ship requires different specifications than a warehouse. Hazardous materials must be placed high on board to make them more accessible, whereas in a warehouse, they are placed as close to the ground as possible to minimize the risk of falls.

Our training and safe storage software is based on Canadian provincial and federal regulations and standards, such as Transportation of Dangerous Goods (TDG), the National Fire Code (NFC) and the Building Code. Many of these standards or regulations refer to the U.S. National Fire Protection Association (NFPA 30).

Kalium solutions ensures that hazardous materials are stored away from incompatible materials and that their storage meets all the requirements of the codes and regulations listed above.

Here are the 5 fundamental steps we apply to ensure the success of your storage:

- Inventory

- Classification

- Identification (labelling)

- Incompatibilities

- The layout of the premises

Kalium can recommend additional safety measures based on the type of hazardous material being stored. For example, flammable materials may require the installation of fire suppression systems, and some highly reactive substances must remain under lock and key, accessible only to certified personnel.

Therefore, it is imperative that a qualified individual handle the categorization of dangerous goods for storage. Since the necessary safety measures vary based on the hazards of the product, incorrect classification can compromise the safety of personnel and property.

All our storage and classification services are performed by experienced chemists.

In addition, our audit service allows us to conduct audits and provide recommendations for correcting dangerous situations in your facilities.

4. What is the importance of chemical storage training?

Proper training in chemical storage is crucial to ensure that employees handle and store hazardous materials safely and in compliance with various codes, standards and regulations. Our training helps prevent accidents in the workplace, promotes proper labelling, ensures proper handling, and equips staff to respond appropriately during emergencies.

Kalium Solutions’ training covers all the essential aspects of safe storage. These include:

- The different regulations concerned

- Risk management

- The different labelling systems

- The particularities of the different hazard classes

- The separation of the incompatible

- Products with specific incompatibilities

- Etc.

Our training is highly detailed and can be customized to your specific workplace needs.

5. Which sectors could gain from Kalium Solutions’ hazardous materials storage software?

Our software solutions are used by companies in various industries for the safekeeping of hazardous materials.

- Pharmaceutical and biotechnology companies (for the storage of chemicals and medicines)

- Industrial facilities and manufacturing plants (for raw materials, finished products, and hazardous and non-hazardous waste).

- The automotive and aviation sectors, which handle hazardous materials such as flammable and corrosive substances,

- Chemical and biological research facilities and laboratories

- The energy and petrochemical industries (for fuel, gas, and reactive chemicals)

6. Can companies tailor their safe storage solution to their particular needs?

Indeed, our software provides tailored hazardous materials storage solutions thanks to its comprehensive reports that facilitate inventory management and incompatibility handling.

Regardless of whether you have one or multiple storage locations, our five-tier location system will give you complete control over your storage. You can pinpoint the location of your product with the precision of the shelf it is on.

Our software allows you to designate a specific area for storing items in a certain hazard class, such as flammables. When adding new goods, it will ensure that the selected storage space meets all necessary safety requirements and regulatory guidelines.

You will have the ability to input the opening and expiration dates for your sensitive products that don’t age well. This will allow you to promptly identify which products require disposal and the precise time frame for doing so.

Reach out to us for a customized solution at 450 906-6999.

Design, programming and hosting by VisionW3.com